The Ziegler–Nichols tuning method is a heuristic method of tuning a PID controller. It was developed by John G. Ziegler and Nathaniel B. Nichols. It is performed by setting the I (integral) and D (derivative) gains to zero. The 'P' (proportional) gain, is then increased (from zero) until it reaches the ultimate gain, which is the largest gain at which the output of the control loop has stable and consistent oscillations; higher gains than the ultimate gain have diverging oscillation. and the oscillation period are then used to set the P, I, and D gains depending on the type of controller used and behaviour desired:

| Control Type | |||||

|---|---|---|---|---|---|

| P | – | – | – | – | |

| PI | – | – | |||

| PD | – | – | |||

| classic PID[2] | |||||

| Pessen Integral Rule[2] | |||||

| some overshoot[2] | |||||

| no overshoot[2] |

The ultimate gain is defined as 1/M, where M = the amplitude ratio, and .

These 3 parameters are used to establish the correction from the error via the equation:

Dec 21, 2012 Hi, I begin to understand thanks to the post. In fact, all algorithms developped in the 'PID and Fuzzy Logic Toolkit' use the 'academic' PID structure.If you want to use Ziegler-Nichols method for autotuning, you will see in litterature that the tables for calculating PID parameters are designed for 'series' PID structure. Standard PID Tuning Methods (tbco 2/17/2012) I. Cohen-Coon Method (Open-loop Test) Step 1: Perform a step test to obtain the parameters of a FOPTD (first order plus time delay) model i. Make sure the process is at an initial steady state ii. Introduce a step change in the manipulated variable iii. A proportional–integral–derivative controller (PID controller or three-term controller) is a control loop mechanism employing feedback that is widely used in industrial control systems and a variety of other applications requiring continuously modulated control. A Control Design reader writes: I often have difficulty tuning PID loops, especially for tem- perature control applications and servo-motor motion applications. If I use a temperature controller, the auto-tune built into the device often works well if I follow the manufacturer’s. Simcet is a real-time, online PID tuning simulator for practice and testing of tuning skills. Tuning PIDs in Simcet is exactly as if you are tuning loops in the real plant. The uniqueness of Simcet is that it also provides testing and grading features to.

which has the following transfer function relationship between error and controller output:

Evaluation[edit]

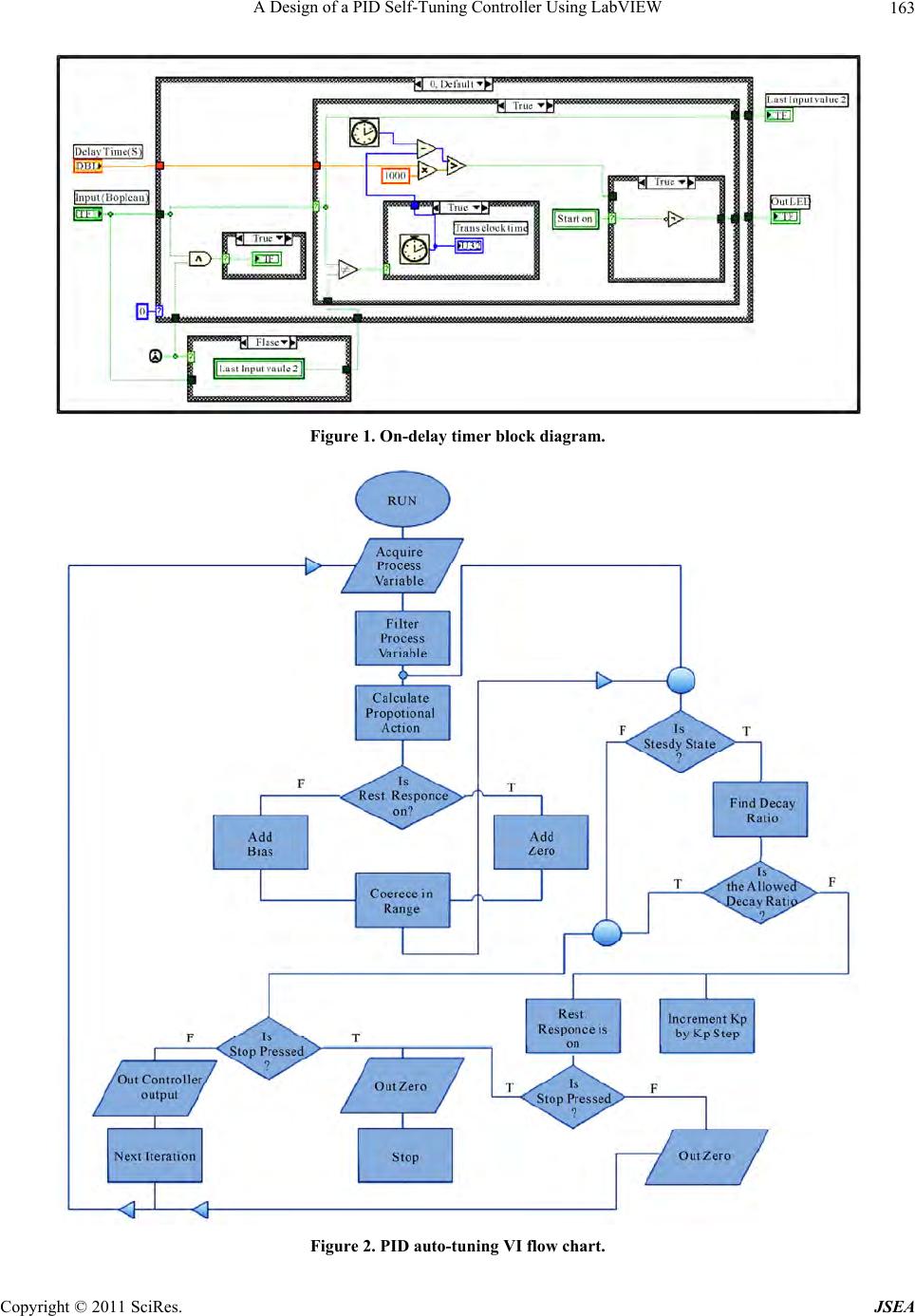

Owning Palette: PID VIs Requires: Full Development System Implements autotuning using the tuning method associated with the polymorphic instance you select. This VI generates PID parameters based on the Stimulus signal and Response signal you specify. You can use this VI to generate initial parameters when you do not have sufficient information about the system you. PID Control Using NI LabVIEW. Figure 2: Effect of PID Controllers on Closed-Loop System. Note that these correlations may not be exactly accurate, because Kp, Ki, and Kd are dependent on each other. In fact, changing one of these variables can change the effect of the other two. For this reason, the table should only be used as a reference.

The Ziegler–Nichols tuning (represented by the 'Classic PID' equations in the table above) creates a 'quarter wave decay'. This is an acceptable result for some purposes, but not optimal for all applications.

This tuning rule is meant to give PID loops best disturbance rejection.[2]

It yields an aggressive gain and overshoot[2] – some applications wish to instead minimize or eliminate overshoot, and for these this method is inappropriate. In this case, the equations from the row labelled 'no overshoot' can be used to compute appropriate controller gains.

References[edit]

- ^Ziegler, J.G & Nichols, N. B. (1942). 'Optimum settings for automatic controllers'(PDF). Transactions of the ASME. 64: 759–768.Cite journal requires

|journal=(help) - ^ abcdefZiegler–Nichols Tuning Rules for PID, Microstar Laboratories

Ni Pid Auto Tuning Tool

- Bequette, B. Wayne. Process Control: Modeling, Design, and Simulation. Prentice Hall PTR, 2010. [1]

- Co, Tomas; Michigan Technological University (February 13, 2004). 'Ziegler–Nichols Closed Loop Tuning'. Retrieved 2007-06-24.

External links[edit]

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

PID tuning refers to the parameters adjustment of a proportional-integral-derivative control algorithm used in most repraps for hot ends and heated beds.

PID needs to have a P, I and D value defined to control the nozzle temperature. If the temperature ramps up quickly and slows as it approaches the target temperature, or if it swings by a few degrees either side of the target temperature, then the values are incorrect.

To run PID Autotune in Marlin and other firmwares, run the following G-code with the nozzle cold:

This will heat the first nozzle (E0), and cycle around the target temperature 8 times (C8) at the given temperature (S200) and return values for P I and D. An example from http://www.soliwiki.com/PID_tuning is:

For Marlin, these values indicate the counts of the soft-PWM power control (0 to PID_MAX) for each element of the control equation. The softPWM value regulates the duty cycle of the f=(FCPU/16/64/256/2) control signal for the associated heater. The proportional (P) constant Kp is in counts/C, representing the change in the softPWM output per each degree of error. The integral (I) constant Ki in counts/(C*s) represents the change per each unit of time-integrated error. The derivative (D) constant Kd in counts/(C/s) represents the change in output expected due to the current rate of change of the temperature. In the above example, the autotune routine has determined that to control for a temperature of 200C, the soft PWM should be biased to 92 + 19.56*error + 0.71 * (sum of errors*time) -134.26 * dError/dT. The 'sum of errors*time' value is limited to the range +/-PID_INTEGRAL_DRIVE_MAX as set in Configuration.h. Commercial PID controllers typically use time-based parameters, Ti=Kp/Ki and Td=Kd/Kp, to specify the integral and derivative parameters. In the example above: Ti=19.56/0.71=27.54s, meaning an adjustment to compensate for integrated error over about 28 seconds; Td=134.26/19.56=6.86s, meaning an adjustment to compensate for the projected temperature about 7 seconds in the future.

The Kp, Ki, and Kd values can be entered with:

In the case of multiple extruders (E0, E1, E2) these PID values are shared between the extruders, although the extruders may be controlled separately. If the EEPROM is enabled, save with M500. If it is not enabled, save these settings in Configuration.h.

For the bed, use:

and save bed settings with:

Ni Pid Auto Tuning Parts

For manual adjustments:

- if it overshoots a lot and oscillates, either the integral gain needs to be increased or all gains should be reduced

- Too much overshoot? Increase D, decrease P.

- Response too damped? Increase P.

- Ramps up quickly to a value below target temperature (0-160 fast) and then slows down as it approaches target (160-170 slow, 170-180 really slow, etc) temperature? Try increasing the I constant.

See also Wikipedia's PID_controller and Zeigler-Nichols tuning method. Marlin autotuning (2014-01-20, https://github.com/ErikZalm/Marlin/blob/Marlin_v1/Marlin/temperature.cpp#L250 ) uses the Ziegler-Nichols 'Classic' method, which first finds a gain which maximizes the oscillations around the setpoint, and uses the amplitude and period of these oscillations to set the proportional, integral, and derivative terms.

Saving PID settings

You will need to commit your changes to EEPROM or your configuration.h file for them to be permanent.

To save to EEPROM use:M500

Modifying Marlin Autotune parameters

The default Marlin M303 calculates a set of Ziegler-Nichols 'Classic' parameters based on the Ku (Ultimate Gain) and the Pu (Ultimate Period), where the Ku and Pu are determined by searching for a biased BANG-BANG oscillation around an average power level that produces oscillations centered on the setpoint. (See https://github.com/ErikZalm/Marlin/blob/Marlin_v1/Marlin/temperature.cpp#L238 )

You can transform these 'Classic' parameters into the Zeigler-Nichols 'Some Overshoot' set with:

Or the Z-N 'No Overshoot' set:

Note that the multipliers for the autotuning parameters each have only one significant digit (implying 10% maximum precision), and that the other schemes differ by factors of 2 or 3. PID autotuning and tuning isn't terribly precise, and changes in the parameters by factors of 5 to 50% are perfectly reasonable.

In Marlin, the parameters that control and limit the PID controller can have more significant effects than the popular PID parameters. For example, PID_MAX and PID_FUNCTIONAL_RANGE, and PID_INTEGRAL_DRIVE_MAX can each have dramatic, unexpected effects on PID behavior. For instance, a too-large PID_MAX on a high-power heater can make autotuning impossible; a too-small PID_FUNCTIONAL_RANGE can cause odd reset behavior; a too large PID_FUNCTIONAL_RANGE can guarantee overshoot; and a too-small PID_INTEGRAL_DRIVE_MAX can cause droop.

Auto Tuning.ro

PID Tuning by Commercial PID

If you have access to a PID controller unit and a compatible thermal probe that fits down into your hotend, you can use them to tune your PID and calibrate your thermistor.

Connection of the output of the PID to your heater varies depending on your electronics. (I used a 1K2:4K7 voltage divider to drop the 22V output of the PID to 5V for my bread-boarded VNP4904)

After the PID is connected you can use it to measure the nozzle temperature and correlate it with the thermistor readings and resistances.

Conversion from the commercial PID values of kP in %fullscale, Ti in seconds, and Td in seconds is as follows:

As an example, a $30 MYPIN TD4-SNR 1/16 DIN PID temperature controller and $10 type-K probe can hold a particular Wildseyed hotend with a 6.8ohm resistor at 185.0C+/-0.1C using 12V with about a 43.7% duty cycle, or 0.437*12*12/6.8=9.25W. Invoking the autotuning on the controller produces these parameters: P=0.8%/C, I=27s, D=6.7s. Converting these to Marlin PID values:

Differences between the results can be caused by physical differences in the systems, (e.g: the thermocouple is closer to the heater than the thermistor,) or by different choices of autotuning parameters (e.g.: the MYPIN TD4 autotuning process is a proprietary black box, while Marlin uses Zeigler-Nichols 'Classic' method.)

The Temperature/resistance table below was developed by using the PID+thermocouple system to set temperatures on a sample hotend by controlling the heater while measuring the thermistor resistance. These values can be used with Nophead's http://hydraraptor.blogspot.com/2012/11/more-accurate-thermistor-tables.html or Marlin's https://github.com/ErikZalm/Marlin/blob/Marlin_v1/Marlin/createTemperatureLookupMarlin.py to create calibrated thermistor tables. The PID column collects the autotuning values produced by the PID controller for the indicated temperature. The kP,Ki,Kd lists the converted parameters.

| Temp | DutyCycle | Thermistor R | Commercial PID | Kp,Ki,Kd |

|---|---|---|---|---|

| 60.0 | 6.0 | 31630 | ||

| 100.0 | 15.7 | 10108 | 1.1%/C, 35.5s, 8.8s | 2.81, 0.08, 3.13 |

| 120.0 | 22.5 | 5802 | 1.0%/C, 32.0s, 8.0s | 2.55, 0.08, 3.14 |

| 135.0 | 26.5 | 3967 | ||

| 150.0 | 28.5 | 2840 | 1.2%/C, 29.0s, 7.2s | 3.06, 0.10, 2.35 |

| 170.0 | 34.0 | 1829 | ||

| 185.0 | 43.7 | 1347 | 0.8%/C, 27s, 6.7s | 2.04, 0.08, 3.28 |

| 190.0 | 45.9 | 1200 | 0.8%/C, 26s, 6.5s | 2.04, 0.08, 3.18 |

| 200.0 | 51.0 | 977 |